Swamp Cooler Repairs Timing

Swamp cooler repairs are most effective when performed during the off-season, typically in early spring or late fall. This timing allows for maintenance and repairs before peak usage periods, ensuring optimal performance during hot weather. Addressing issues beforehand can prevent unexpected breakdowns and extend the lifespan of the cooler.

Performing repairs in spring prepares the cooler for the upcoming hot season, reducing the risk of malfunction during peak use.

Late fall repairs help address any issues after heavy usage and prepare the unit for storage or less frequent use.

Repairs during the off-season often allow for quicker service and less scheduling conflict.

Early repairs can prevent costly breakdowns and improve energy efficiency.

Technicians inspecting a swamp cooler in early spring.

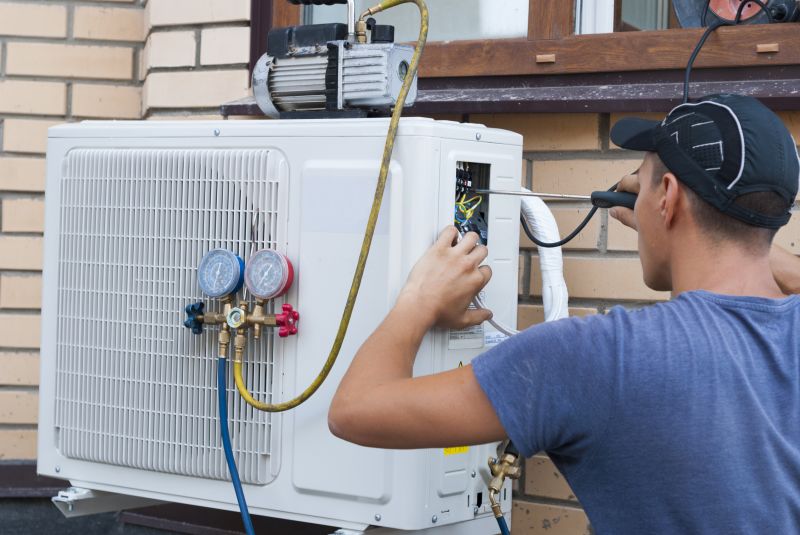

A technician performing maintenance during fall.

A swamp cooler being serviced before peak season.

Ways to make Swamp Cooler Repairs work in tight or awkward layouts.

Popular materials for Swamp Cooler Repairs and why they hold up over time.

Simple add-ons that improve Swamp Cooler Repairs without blowing the budget.

| Best Time for Repairs | Advantages |

|---|---|

| Early Spring | Prepares the cooler for the hot season, reduces breakdown risk. |

| Late Fall | Addresses issues after heavy use, ready for storage or less use. |

| Off-Season | Easier scheduling and quicker service. |

| Avoid Extreme Weather | Repairs during moderate weather ensure safety and effectiveness. |

| Pre-Season | Ensures optimal cooling performance during peak months. |

Swamp cooler repairs involve various components, including the water pump, pads, motor, and fan. Regular maintenance can improve efficiency, reduce energy costs, and prevent costly replacements. Statistics indicate that timely repairs can extend the lifespan of a swamp cooler by several years and improve cooling performance by up to 20%. Properly maintained units also consume less energy, resulting in lower utility bills.

Replacement parts being installed in a cooling unit.

Technician inspecting the water pump.

Cleaning the cooling pads for optimal performance.

Final check to ensure proper functioning.

High-end options that actually feel worth it for Swamp Cooler Repairs.

Finishes and colors that play nicely with Swamp Cooler Repairs.

Little measurements that prevent headaches on Swamp Cooler Repairs day.

A 60-second routine that keeps Swamp Cooler Repairs looking new.

Interested in swamp cooler repairs? Filling out the contact form can provide more information and schedule a service appointment. Proper timing and maintenance are essential for reliable cooling during the hottest months.